- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Aksesori alat mesin Pengeluar, Pembekal, Kilang

As the pivotal equipment in precision machining, the accuracy of CNC machine tools bears a direct correlation to product quality. To attain high-precision operation, in addition to the superior performance of the machine tool itself crucial, its compatible accessories are also equally indispensable.

The significance of CNC machine tool accessories lies in several aspects:

(1) Enhancing Machining Accuracy

Proper machine tool accessories can compensate for the limitations of CNC machine tools in specific respects, thereby further elevating their machining accuracy.

(2) Boosting Production Efficiency

In the production process, effective coordination among machine tool accessories ensures smoother processing flows of CNC machine tools, minimizing unnecessary downtimes and auxiliary operations.

(3) Expanding Processing Capabilities

The integration of CNC machine tools with diverse types of accessories broadens their processing horizons, allowing them to tackle a wider array of parts with more intricate shapes.

The importance of CNC machine tool accessories

(1) Improve machining accuracy

Appropriate machine tool accessories can make up for the shortcomings of CNC machine tools in certain aspects and further improve their machining accuracy.

(2) Improve production efficiency

During the production process, the effective coordination of machine tool accessories can make the processing flow of CNC machine tools smoother and reduce unnecessary downtime and auxiliary operations.

(3) Expand processing capabilities

The combination of CNC machine tools and different types of machine tool accessories can expand the processing capabilities of the machine tools, enabling them to complete the processing of more types of parts with more complex shapes.

Qingdao Micro Precision Machinery Co. is ready to offer high precision CNC machine tool accessories to customers worldwide.

For 24 hours contact details as below:

Email: cyndee@wghydrauliccylinder.com

sales@wghydrauliccylinder.com

Mobile/whatsApp/Wechat: 0086-13793230712

- View as

Pemegang Alat Kunci Side

Pemegang alat kunci sampingan adalah sejenis pemegang alat pemotong biasa, digunakan secara meluas dalam pelbagai mesin CNC. Ia dikunci oleh skru penetapan sampingan, mudah dibongkar dan dipasang, dengan kekuatan ketepatan dan pengapit yang tinggi. Ia sesuai untuk proses pemotongan berat. Ia juga dipanggil pemegang kilang akhir atau penyesuai. Pemegang alat boleh disesuaikan dengan saiz yang berbeza seperti keperluan pelanggan.

Baca LagiHantar PertanyaanAdalah collet siri

ER Series Collet adalah collet silinder yang digunakan pada alat mesin, terutamanya untuk mengamankan dan mengepung alat penggerudian dan penoreh atau alat penggilingan.

Collet boleh disesuaikan dengan saiz yang berbeza sebagai keperluan pelanggan.

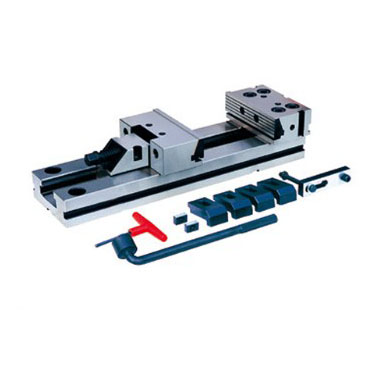

Kombinasi Modular Gabungan Ketepatan

ZZ-00336 Kombinasi Modular Kombinasi Precision diperbuat daripada keluli aloi berkualiti tinggi, kekerasan kerja permukaan HRC58-622, Parallelism 0.0005mm/100mm, menegak 0.005m3. Dengan pangkalan yang boleh ditanggalkan, rahang tetap, rahang bergerak, pengetatan cepat, operasi mudah. Digunakan secara meluas di Pusat Pemesinan pada Alat Mesin Precision.

Baca LagiHantar PertanyaanZQ83 Tindakan Tindakan Single dan Double

ZQ83 Tindakan Tindakan Single dan Double diperbuat daripada keluli aloi berkualiti tinggi, kekerasan permukaan kerja HRC58-62. Mereka digunakan secara meluas di pusat pemesinan, mesin penggilingan CNC, mesin membosankan, penggiling dan alat mesin lain.

Baca LagiHantar PertanyaanZQ80 Vises gabungan menegak dan mendatar

ZQ80 Vise gabungan menegak dan mendatar digunakan di pusat pemesinan, mesin penggilingan CNC, mesin membosankan, pengisar dan alat mesin lain.

Baca LagiHantar PertanyaanQGG Series Precision Tool Vises

QGG Series Precision Tool Vises ZZ-00330 alat ketepatan vises digunakan untuk pengukuran dan pemeriksaan ketepatan, pengisaran ketepatan dan percikan elektrik. Sama ada seimbang, tegak atau rata semasa kerja, ia dapat mengekalkan ketepatan yang tinggi.

Baca LagiHantar Pertanyaan